CAT Longwall Shearer EL1000

Your shearer is the most critical part of your longwall production process. That's why high-performance longwall operations demand shearers that deliver the highest productivity, availability and reliability. Cat shearers were always designed to meet these demands. But Caterpillar has taken them to the next level.

SURVIVAL OF THE FITTEST - To do this, we invested heavily in refining our successful range of shearers. We started by reviewing and analyzing all more recent shearer installations and setting goals to improve productivity, availa¬bility and reliability. This was not a re design, but an evolution – keeping the best tried-and tested features of the existing design while using the latest findings from science and technology to improve features and add new ones.

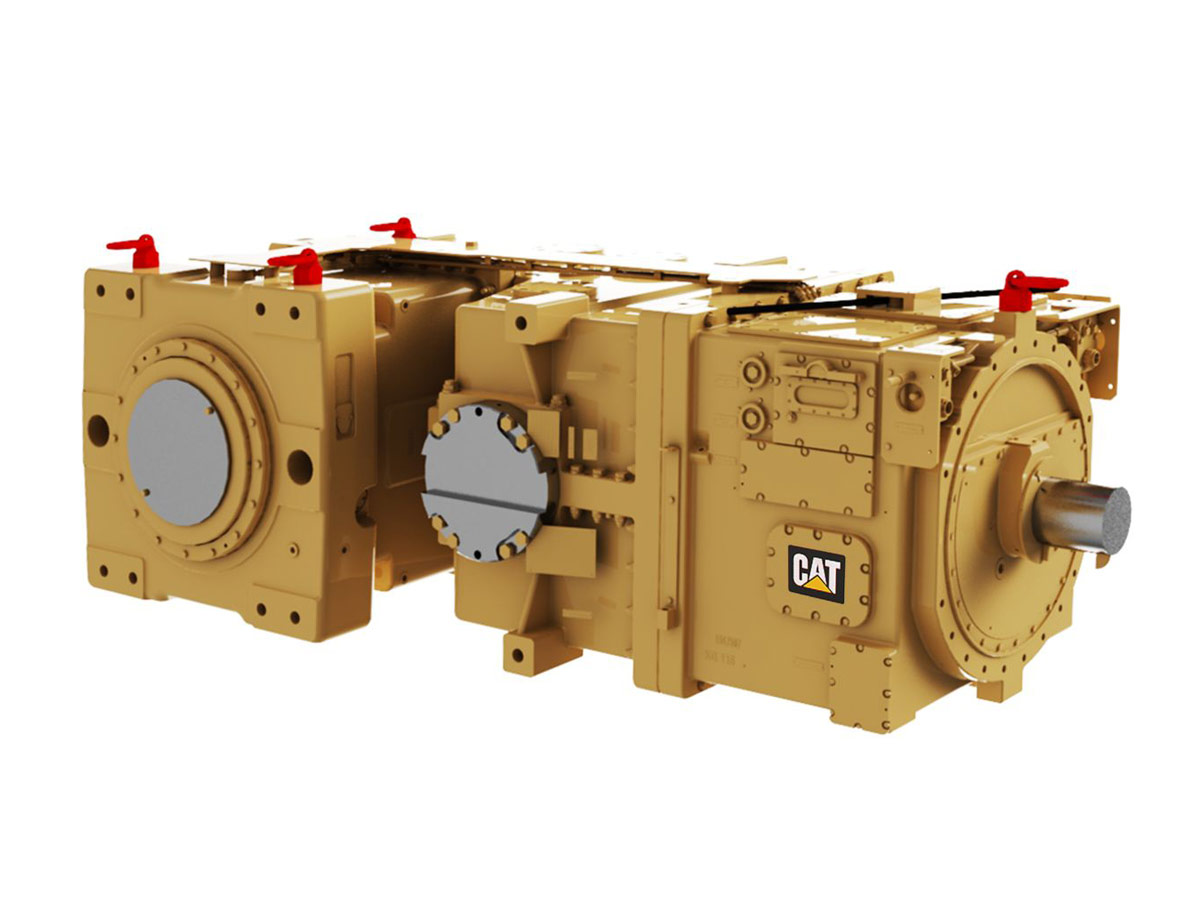

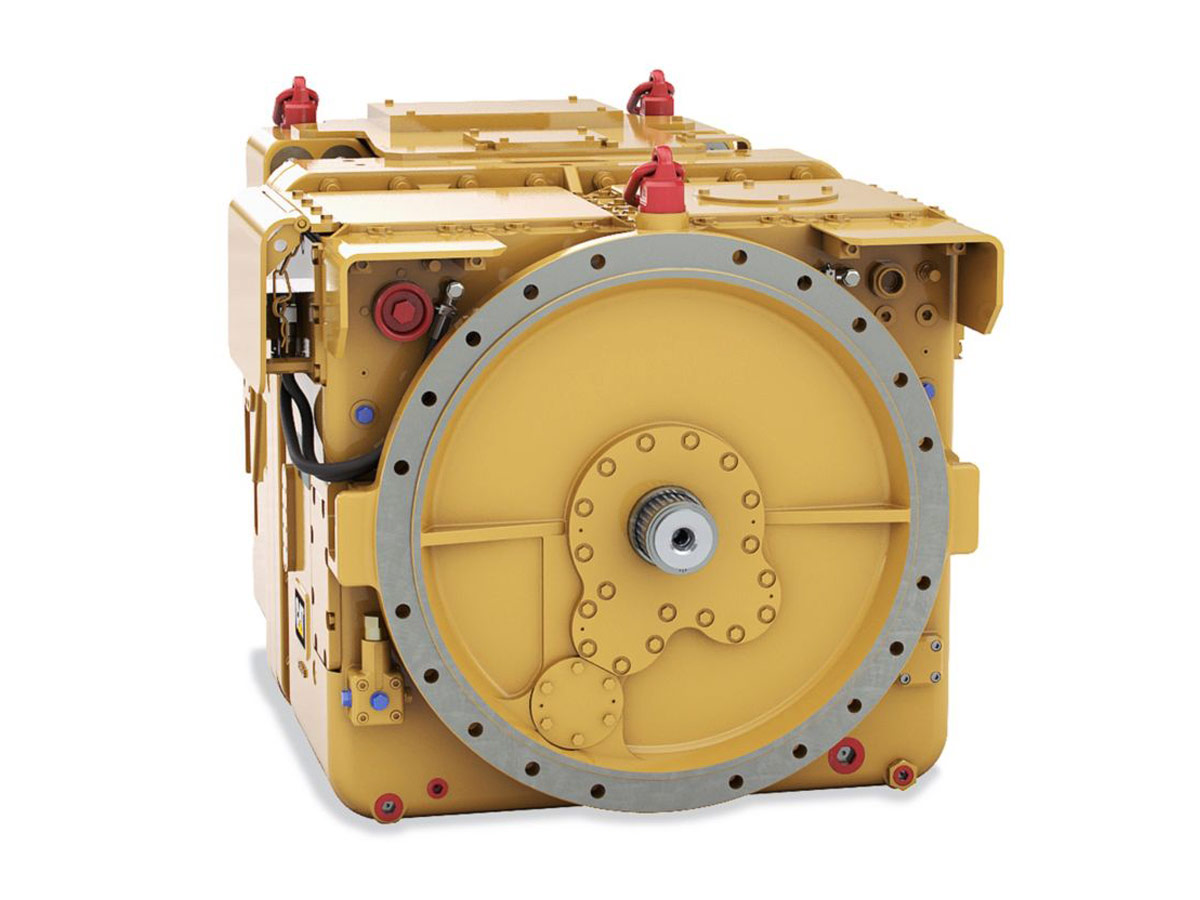

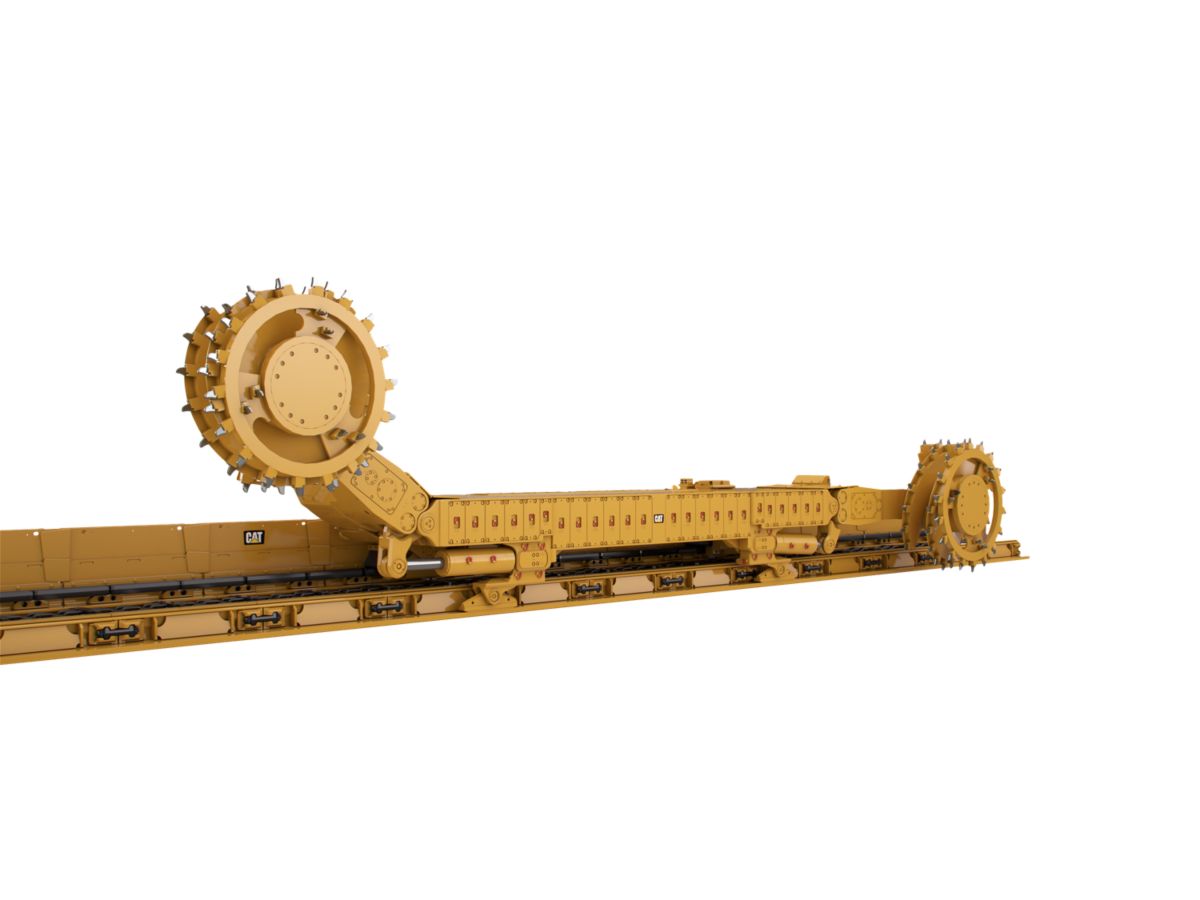

SHEAR PERFORMANCE - With high-powered ranging arms and haulage units, Cat shearers cut and load up to 5000 tons (5,500 tons) per hour and more, depending on mining conditions. The unique, one-piece mainframe design offers maximum structural integrity and service life. The mainframe is available as a split unit in the event of transportation limitations. Featuring the superior Jumbo track shearer haulage system, the shearer also offers advanced integrated automation and communication options.

Overview

Your shearer is the most critical part of your longwall production process. That's why high-performance longwall operations demand shearers that deliver the highest productivity, availability and reliability. Cat shearers were always designed to meet these demands. But Caterpillar has taken them to the next level.

SURVIVAL OF THE FITTEST - To do this, we invested heavily in refining our successful range of shearers. We started by reviewing and analyzing all more recent shearer installations and setting goals to improve productivity, availa¬bility and reliability. This was not a re design, but an evolution – keeping the best tried-and tested features of the existing design while using the latest findings from science and technology to improve features and add new ones.

SHEAR PERFORMANCE - With high-powered ranging arms and haulage units, Cat shearers cut and load up to 5000 tons (5,500 tons) per hour and more, depending on mining conditions. The unique, one-piece mainframe design offers maximum structural integrity and service life. The mainframe is available as a split unit in the event of transportation limitations. Featuring the superior Jumbo track shearer haulage system, the shearer also offers advanced integrated automation and communication options.