Drive Train

Cat® Drive Train parts are high performance and built to last under incredible stress. Final drive and transmission parts work together to transmit power to the ground and propel Cat earthmoving equipment through a variety of applications all over the world. Genuine Cat drive train parts, along with excellent maintenance and repair options, result in maximum productivity and lower owning and operating costs. Drive train components must endure: 1) Incredible torque 2) High impact loads 3) Frequent direction and gear changes Caterpillar designs and manufactures its transmissions and final drive components with these demands in mind. The result is a drive train that lasts longer and works harder over the life of your machine.

Get a Quote- Transmissions

- Torque Converters

- Drive Shaft

- Differential

- Final Drive

- Brakes

Transmissions

The power coming from the engine must be turned into useful power by controlling its speed, direction and force. Transmissions do this by various means: hydraulically engaged planetary clutches and hydrostatic/ hydraulic drive. Each of these methods provides different characteristics of ground speed, torque, clutches maneuverability, and implement force. Because of the wide variety of work they do, Caterpillar products use several types of transmissions; each designed to convert engine power into the exact combination of speed and force required by individual machines. The power coming from the engine must be turned into useful power by controlling its speed, direction and force. Because of the wide variety of work they do, Cat products use several types of transmissions; each designed to convert engine power into the exact combination of speed and force required by individual machines.

Torque Converters

The power that is produced in the engine is multiplied in the torque converter and then transferred on to the transmission for use by the rest of the drive train components. Some Cat machines use a torque divider instead of the traditional torque converter, which divides the transmitted torque between the front and rear axles, with the rear receiving the majority.

Basic Components

- Impeller

- Turbine

- Stator

- Key Functions

- Connects engine and transmission

- Transmits the power from the engine to the transmission

- Multiplies power produced in engine

Drive Shaft is a means of connecting drive train components. It allows for misalignment in the drive. The output shaft connects to the transmission through a yoke and drive shaft or directly to the transmission input gear. Caterpillar’s exact design for proper measurements and precise machining ensures proper gear alignment. Special heat treatment achieves proper surface hardness, core hardness, and hardened depth. The differential will decrease the speed and increase the torque as needed for each wheel & motion adjustment. When the machine is turning the differential will supply the needed adjustments to the wheels allowing the outside wheel to move at a faster pace than the inside wheel.

The key functions of a differential are:

- Transferring power coming from the transmission to the left and right axle shafts.

- Balancing the power accordingly to the demand of each wheel.

- Gears in differential further reduce the speed and increases the torque to drive the rear wheels.

The components of the differential are

- Differential case assembly

- Pinion gears

- Side gears

- Spider

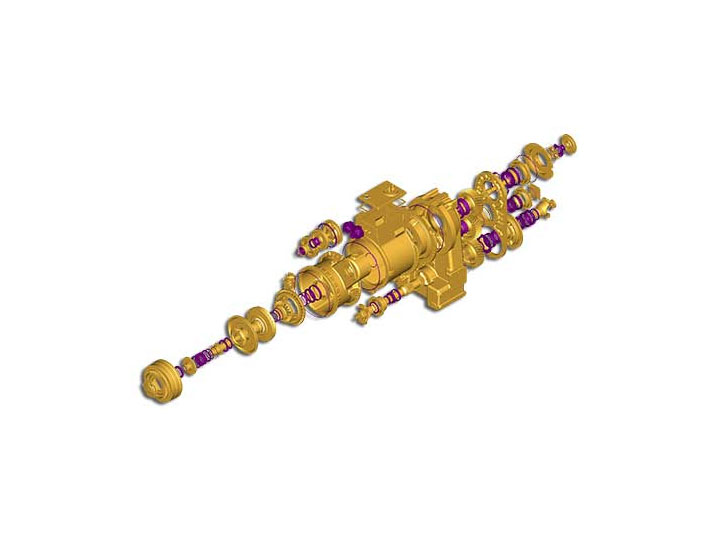

The final drives are an important part of the drive train. They’re the components that apply driving force to the wheels or tracks. The final drives of a track-type tractor differ somewhat, but they perform the same function. They reduce rotating speed and increase torque. In fact, this is where the greatest torque rise occurs…in the gears. That allows these components ahead of the final drives to be smaller, which saves weight and space.

There are four types of final drives used in Cat machines:

- Bull Gear Single Reduction

- Bull Gear Double Reduction

- Planetary Single Reduction

- Planetary Double Reduction

- Expanding shoe

- Caliper Disc

- Wet Disc

- Expander Tube

Brakes are the components that slow, stop or hold a machine stationary. On Cat machines they are located at the wheels of wheel-type machines such as this off-highway mining truck. In track-type machines, they are located on the axle shafts. Brakes usually work by pressing a non-rotating surface, such as a brake shoe, against a rotating surface, in this case, a brake drum. The resulting friction stops the machine. At this point where the two meet, the inertial force of the machine is sometimes converted into bake-oven heat. The braking requirements of various types of machines differ, chiefly because of differences in the work they do. To assure each type of machine has the braking system that best suits its needs, Caterpillar uses four types: