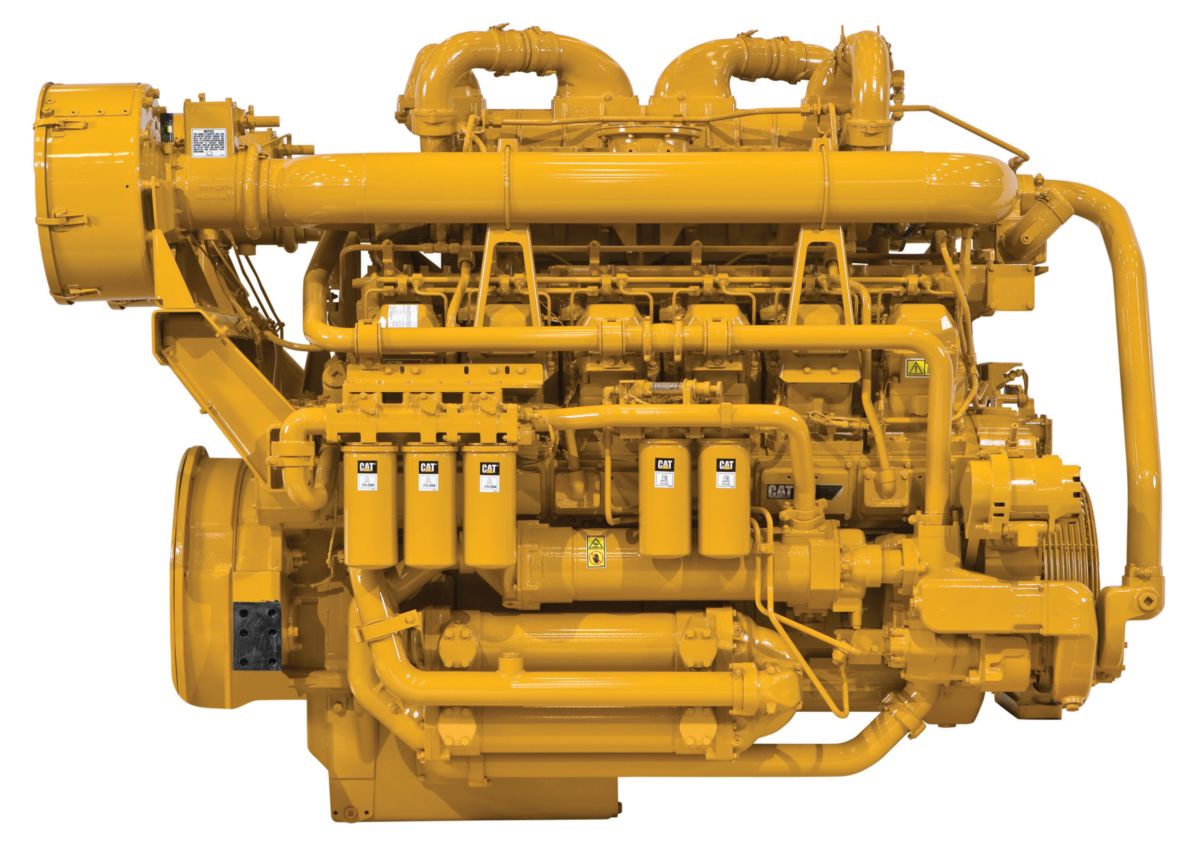

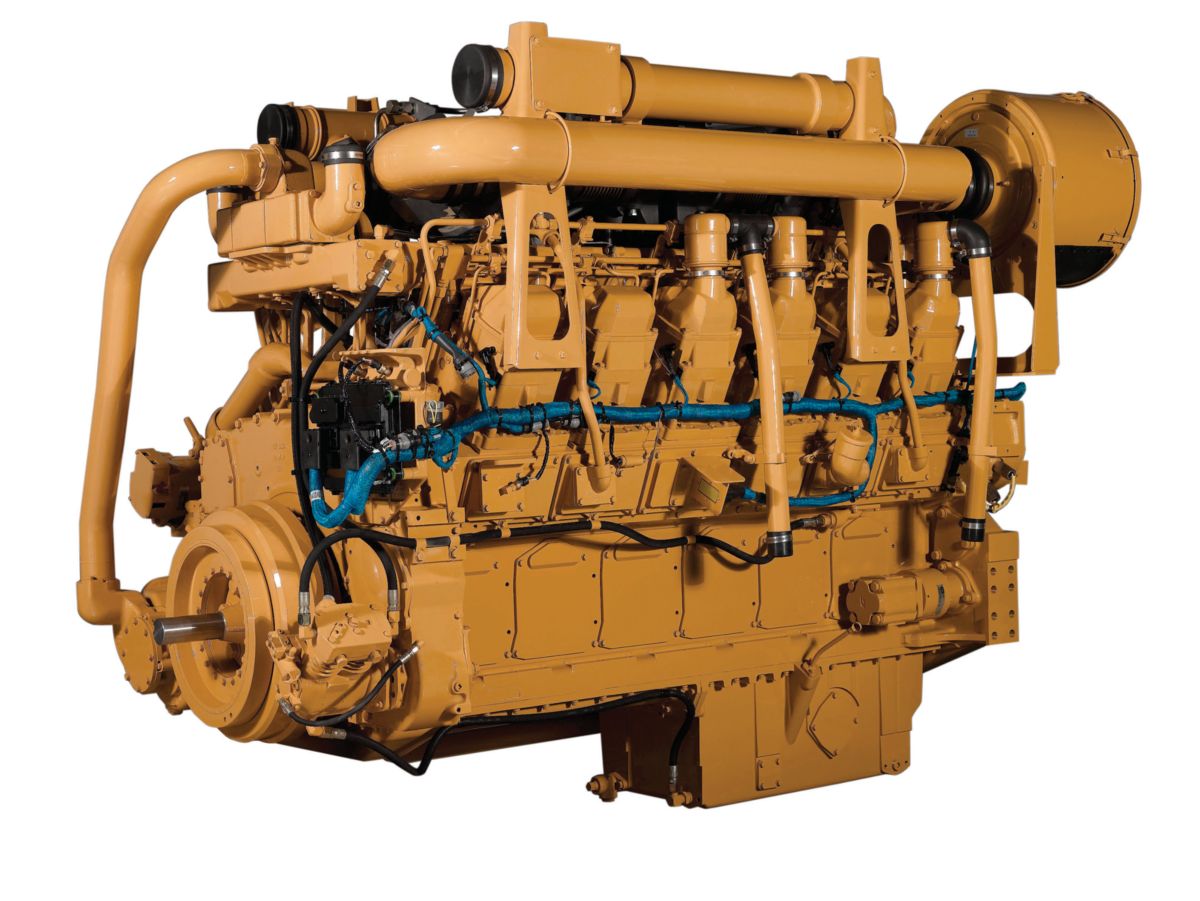

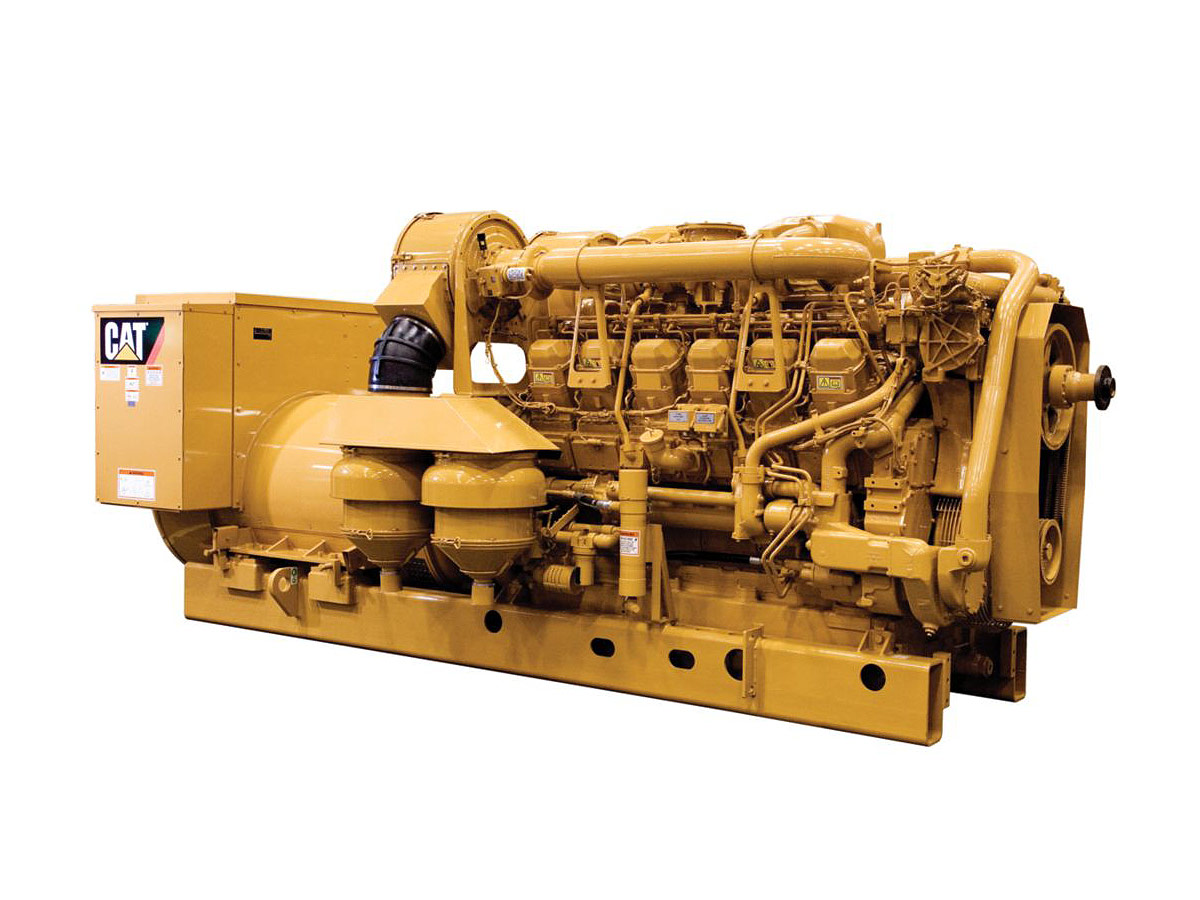

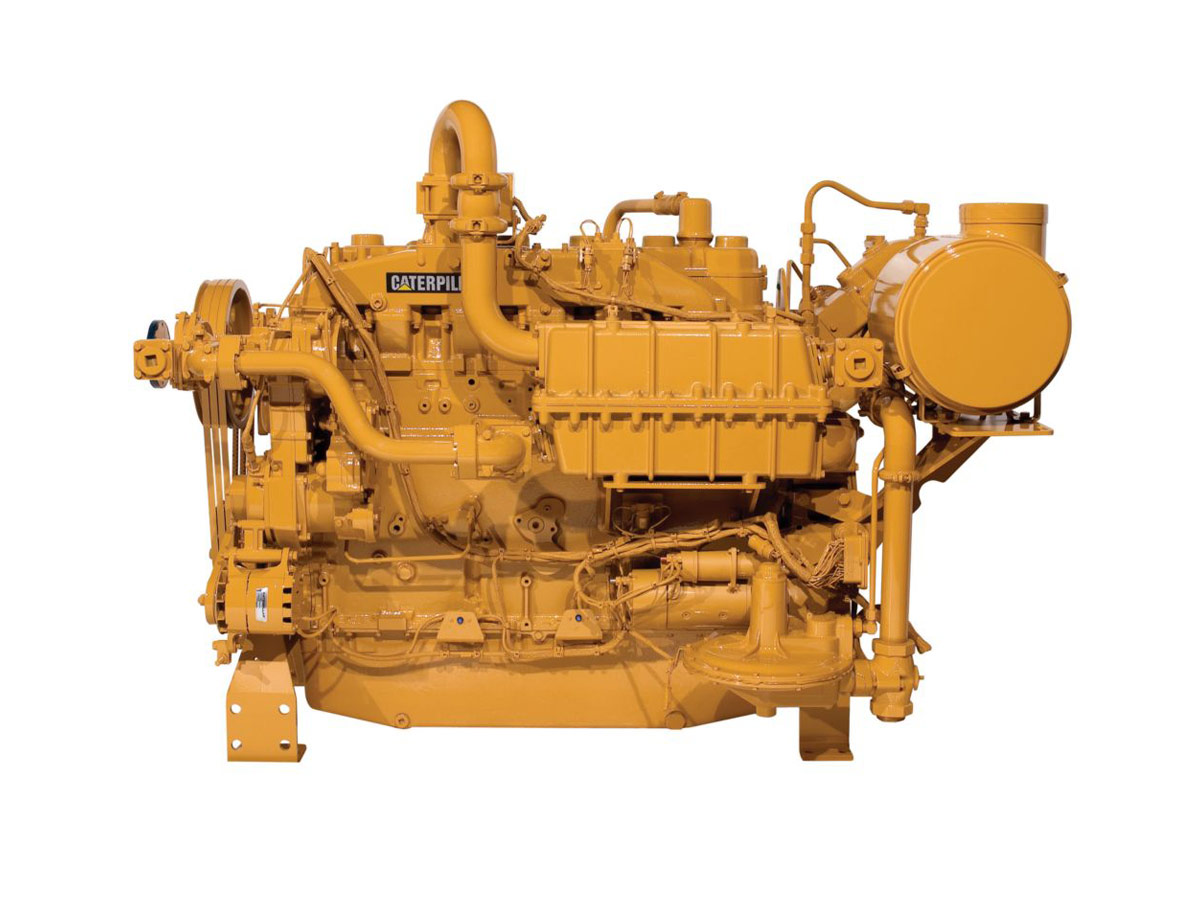

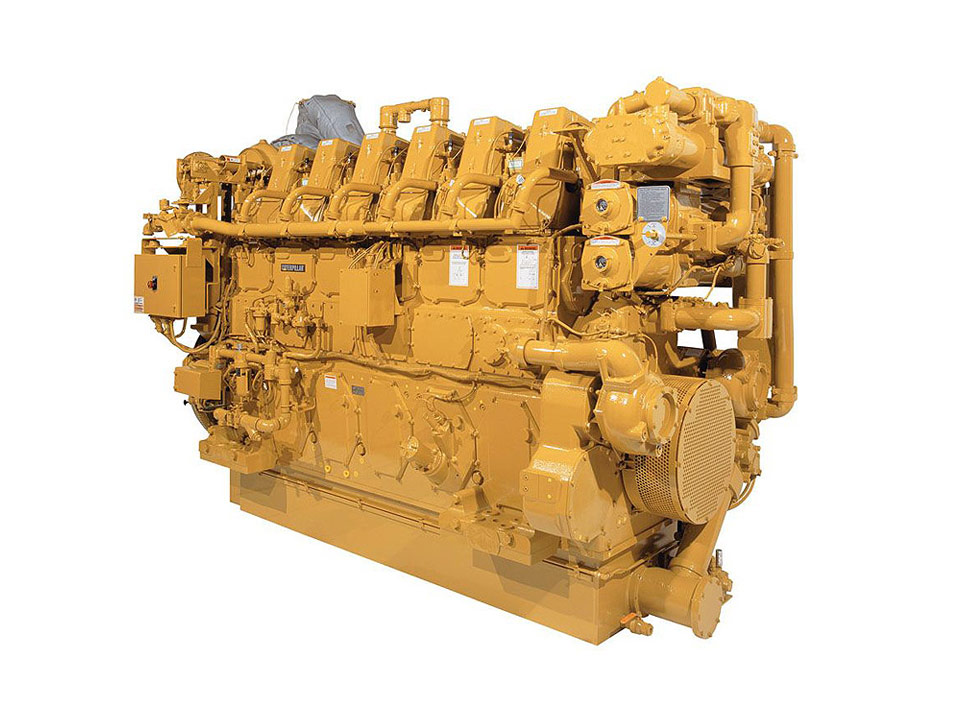

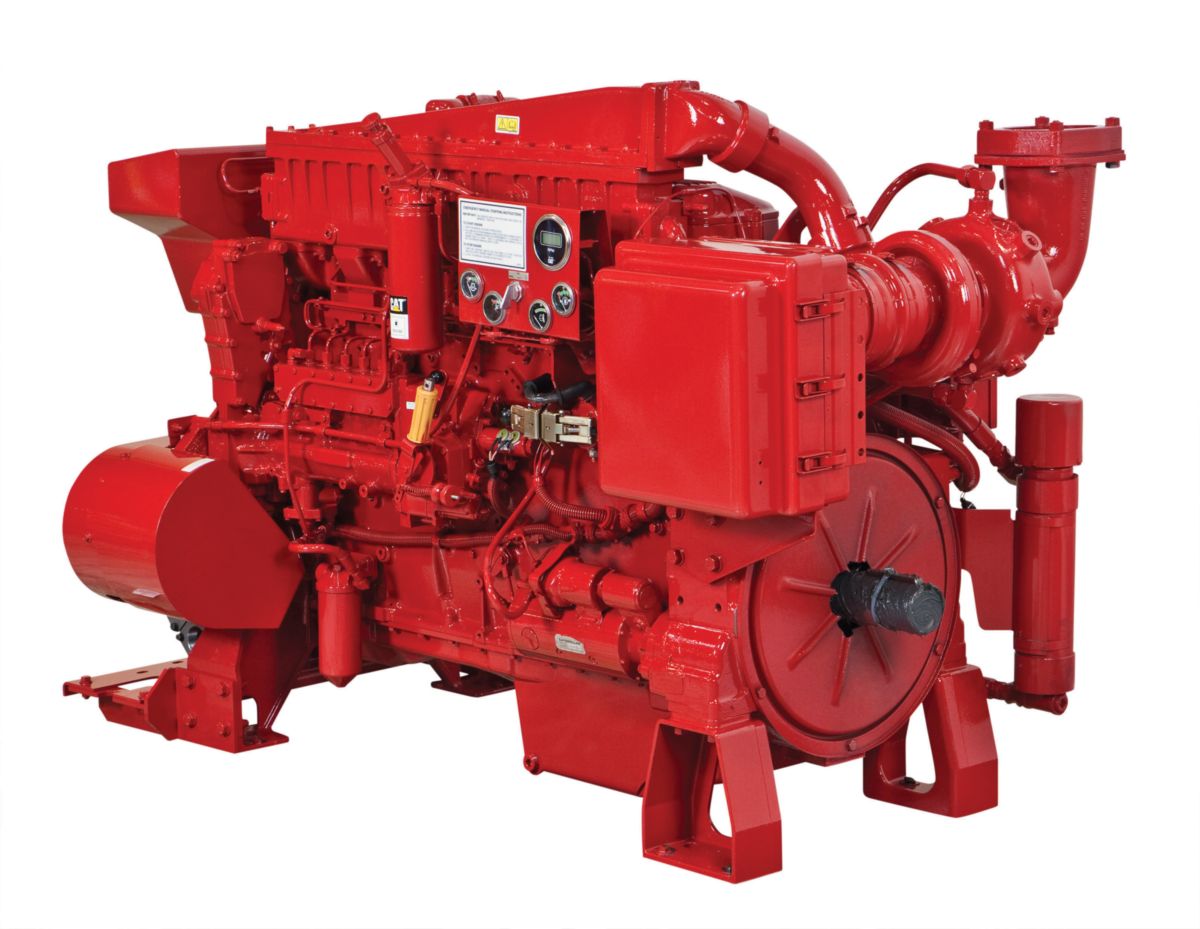

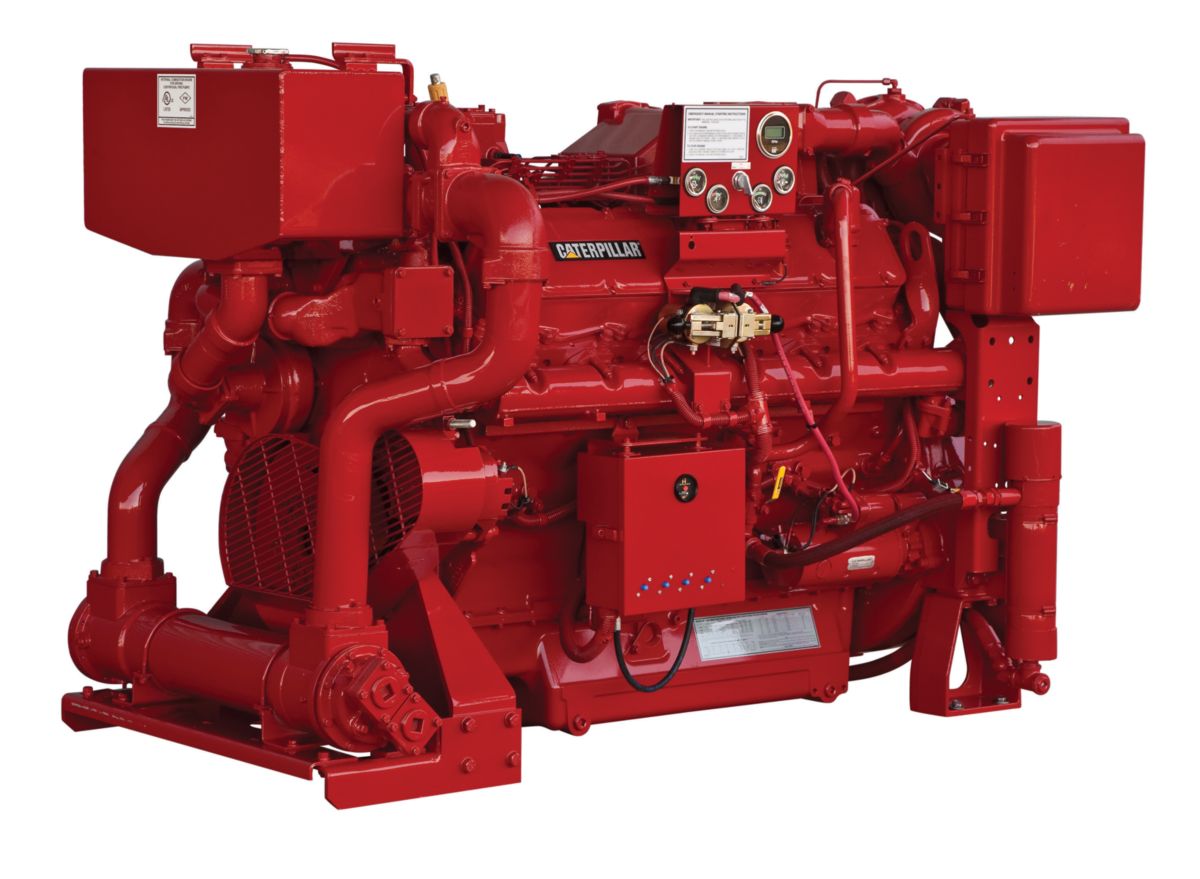

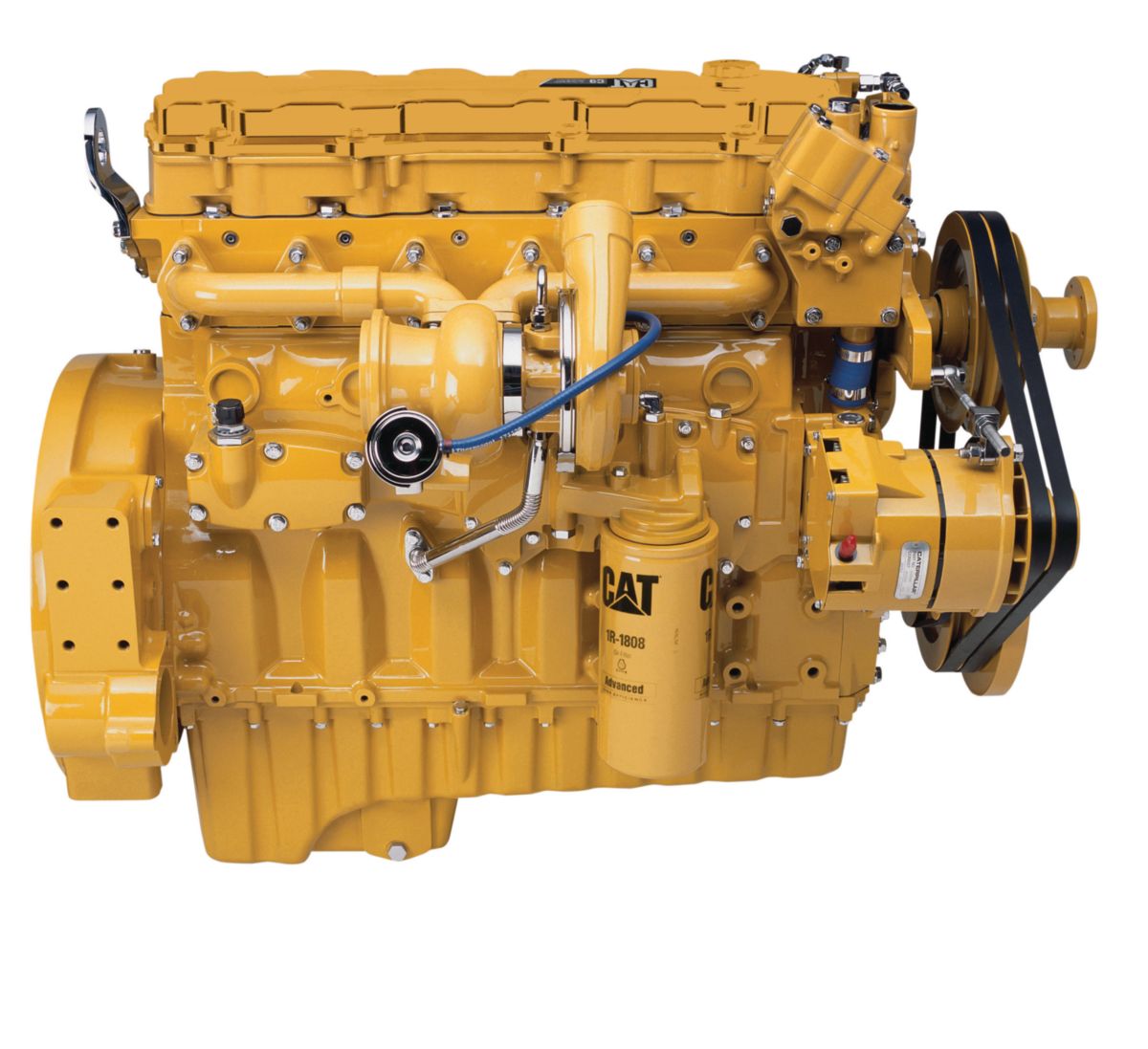

CAT Dry Manifold Engine C9 ACERT

Cat C9 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C9 ACERT engines to deliver excellent performance with low operating costs and emissions. Equipment powered by C9 ACERT engines include workover rigs, pump skids, acidizing units, cementing units, coil tubing units, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. C9 ACERT engines, with ratings: 205-280 bkW (275-375 bhp) @ 1800-2200 rpm, meet China Stage II, EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. U.S. EPA Tier 3 equivalent and EU Stage IIIA equivalent ratings are available using U.S. EPA and EU Flexibility. They are also available in other regulated and non-regulated areas.

Get a QuoteOverview

Cat C9 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C9 ACERT engines to deliver excellent performance with low operating costs and emissions. Equipment powered by C9 ACERT engines include workover rigs, pump skids, acidizing units, cementing units, coil tubing units, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. C9 ACERT engines, with ratings: 205-280 bkW (275-375 bhp) @ 1800-2200 rpm, meet China Stage II, EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. U.S. EPA Tier 3 equivalent and EU Stage IIIA equivalent ratings are available using U.S. EPA and EU Flexibility. They are also available in other regulated and non-regulated areas.