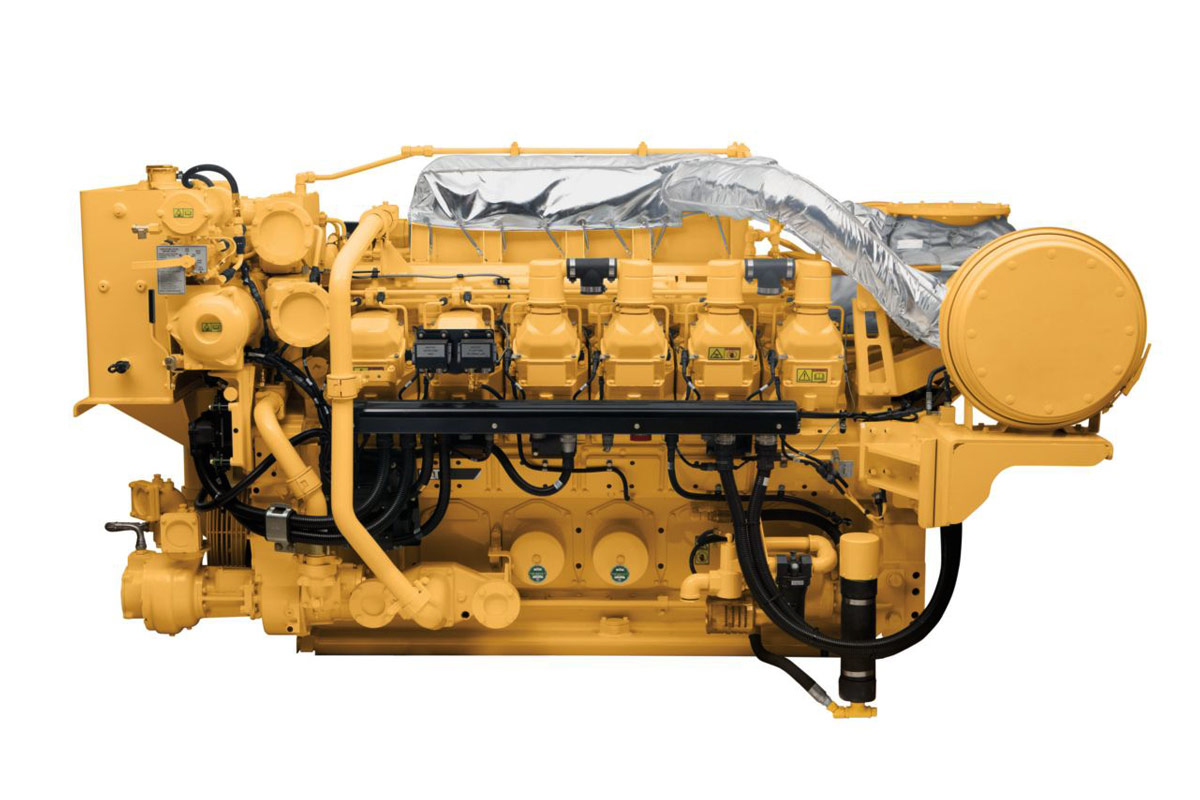

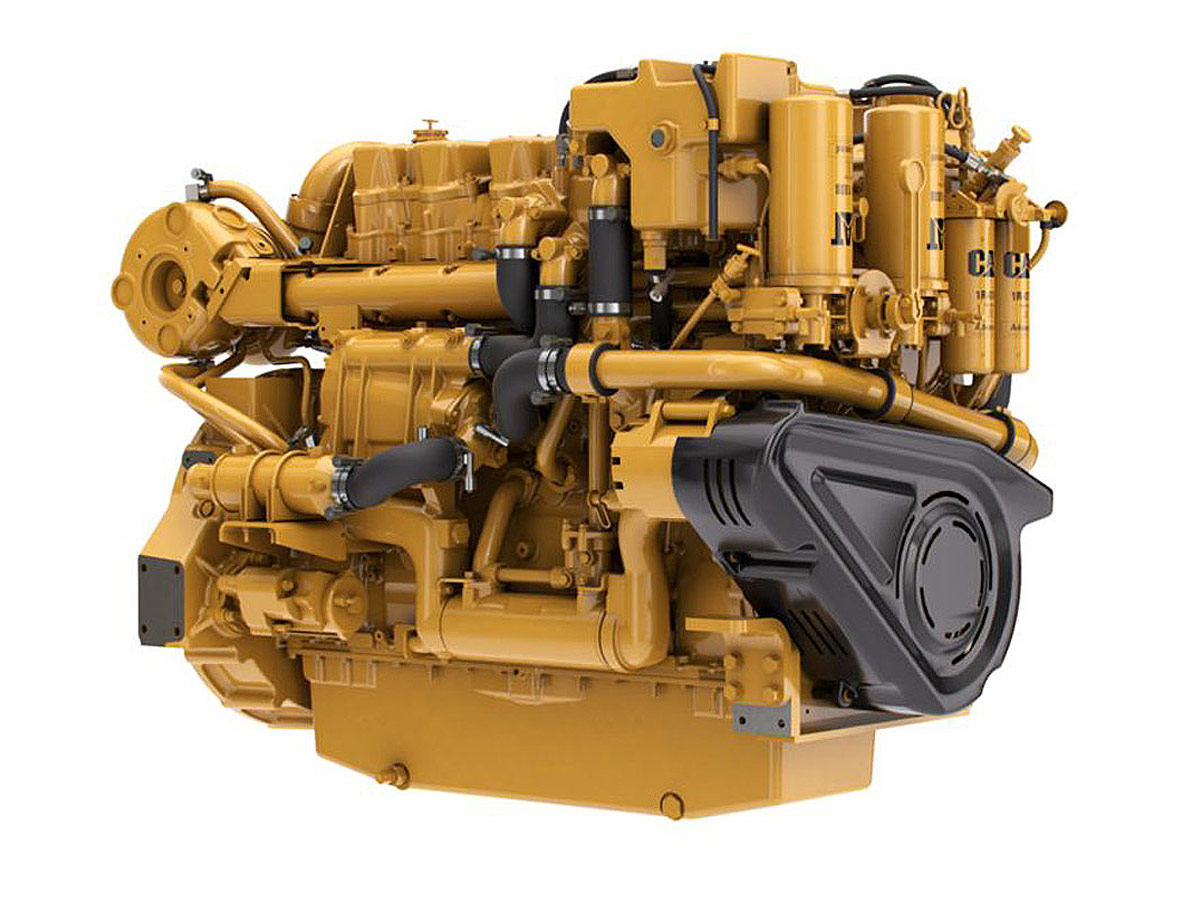

CAT Marine Generator Set C4.4 ACERT

The C4.4 ACERT marine genset packages with heat exchanger or keel cooling are available with 60 Hz ratings of 60, 75, 99, 118 ekW and 50 Hz ratings of 65, 80, 99 ekW. Radiator cooled gen sets are with 60 Hz ratings of 51, 66, 90, and 105 ekW and 50 Hz ratings of 58, 73, and 88 ekW. The C4.4 ACERT meets U.S. EPA Tier 3 and EU CCNR Stage II emissions regulations. The C4.4 ACERT is electronically controlled with a Common Rail fuel system.

Get a QuoteOverview

The C4.4 ACERT marine genset packages with heat exchanger or keel cooling are available with 60 Hz ratings of 60, 75, 99, 118 ekW and 50 Hz ratings of 65, 80, 99 ekW. Radiator cooled gen sets are with 60 Hz ratings of 51, 66, 90, and 105 ekW and 50 Hz ratings of 58, 73, and 88 ekW. The C4.4 ACERT meets U.S. EPA Tier 3 and EU CCNR Stage II emissions regulations. The C4.4 ACERT is electronically controlled with a Common Rail fuel system.

Generator Set Dimensions

Engine Specifications

Generator Specifications

Generator Set Specifications

Generator Set Configurations

Noise Reduction

New block for low noise and vibrations, Insulated timing case cover, Isolated oil pan (also provides ease of maintenance), Improved pump and gear train system, Stiffer crankshaft, Multiple fuel injection strategy, 4 valve cross flow head, Double curvature on thick walled crankcase, Piston optimized for high speed operation

Hydraulic Tappets

Hydraulic tappet adjustment removes the need for manual tappet adjustment, that on the 1006 (C6.6) needed to happen every 500 hours. This system is operated by oil pressure, and this saves the customers a considerable amount of cost from an Operating perspective.

Improved Smoke Levels

Improved smoke levels from C4.4 mechanical engine

Serpentine Belts To Achieve Longer Service Intervals

These belts are more efficient, as they provide more drive surface. Less heating is created during running, and the belt will also last longer. The poly V belt cannot twist over like a single V belt, and any wear of the poly V belt becomes apparent a long time before failure.

Integrated Base Frame

Suitable for wide range of auxiliary accessories

Gear Driven Water Pumps

Lower servicing costs, reduced down time

Water-Cooled Turbo

Suitable for “gas tight” applications

Tailored Technology

Meets customer requirements in: voltage, cooling, twin pocket fly wheel housing, and factory options for starting

Caterpillar Package

Fully packaged generator set

Advanced Fuel And Combustion System With 4 Valves Per Cylinder

Lube System

Oil system holds 11L (2.8 gal), 500-hour oil change interval, Max continuous operation angle is 25? (any direction), Max intermittent operation angle 30? (any direction), Simplex and Duplex oil filters options available.

Design Features

Control panel standard on LHS with single leg box, Control panel location interchangeable between 3 positions available as option.